Step one: find your ribbon

I chose a light blue sheer ribbon and a white satin ribbon so that I could see the light blue ribbon. My dress also has a sheer organza overlay and has around the same color of blue already in the dress so this works well. I believe I chose a 1-1/2" wide ribbon for both and bought at least a 4 yard spool.

Step two: sewing together

This is where the doodles come in because I just went for it, sewed it all up and then realized I should have taken photos. Line up the sheer ribbon on top of the white satin ribbon and sew straight across the ends to have them together. Make sure that they're aligned because this is a guide for sewing the rest together.

This is where the doodles come in because I just went for it, sewed it all up and then realized I should have taken photos. Line up the sheer ribbon on top of the white satin ribbon and sew straight across the ends to have them together. Make sure that they're aligned because this is a guide for sewing the rest together.Step three: the pull

I call it the pull because later, after all the sewing is finished, you will be pulling this to turn the ribbon right side out. Pretty straight forward, find something long, durable and thin like twine or thick string and also sew straight across this to the ends that you just sewed together. Make sure the pull is secure so you don't loose it while turning the ribbon right side out, this may require you to do a few passes over it with the sewing machine.

I call it the pull because later, after all the sewing is finished, you will be pulling this to turn the ribbon right side out. Pretty straight forward, find something long, durable and thin like twine or thick string and also sew straight across this to the ends that you just sewed together. Make sure the pull is secure so you don't loose it while turning the ribbon right side out, this may require you to do a few passes over it with the sewing machine.Step three: fold

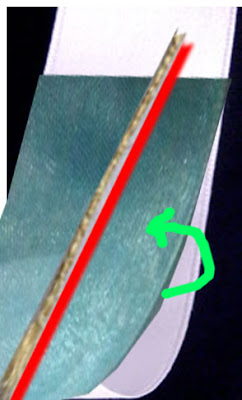

Fold the ribbon over the twine hot dog style so that the twine is

on the inside with the ribbon you eventually want to be on the outside. If you want to, take the iron to the fold so you get a crease and make it easier on yourself in the next step. I didn't do this and I wished later that I had individually ironed a crease into the layers because it probably would have made things easier. Oh well, live and learn.

on the inside with the ribbon you eventually want to be on the outside. If you want to, take the iron to the fold so you get a crease and make it easier on yourself in the next step. I didn't do this and I wished later that I had individually ironed a crease into the layers because it probably would have made things easier. Oh well, live and learn.Step four: lots of sewing

This requires lots of patience because you need to make sure you are sewing both sides of the ribbon sandwiched inside and ribbon currently outside without running over your pull all while trying to get the stitch as straight as possible. Don't worry if you don't get everything completely straight because no one will really notice unless they look over the entire length and are looking for imperfections.

This requires lots of patience because you need to make sure you are sewing both sides of the ribbon sandwiched inside and ribbon currently outside without running over your pull all while trying to get the stitch as straight as possible. Don't worry if you don't get everything completely straight because no one will really notice unless they look over the entire length and are looking for imperfections.Step five: pull the pull

VERY CAREFULLY pull on the other end of the pull that is not sewn down so that the ribbon on the sewn end starts to roll inside to turn the ribbon right side out. This also requires lots of patience but doesn't take nearly as long to do as the sewing.

VERY CAREFULLY pull on the other end of the pull that is not sewn down so that the ribbon on the sewn end starts to roll inside to turn the ribbon right side out. This also requires lots of patience but doesn't take nearly as long to do as the sewing.Step five: spot check

Most likely there will be one or two places that the organza ribbon did not get sewn into the satin ribbon. Calmly and patiently turn the ribbons inside out until you get to the trouble spot, pop some of the seam until you can correct the positioning of the ribbon and run it over with the sewing machine again. Turn it right side out and double check the correction.

Step six: iron

What I did to help was grab a long metal rod, feed it all the way through and used it to make sure everything inside was laying flat and not bunched up. I ironed on a medium heat to crease everything and made sure my seam remained on the same side and didn't twist around as I removed the rod and then went over it a second time to be sure. It does have some areas that are a bit chunkier than others but you can't really tell in this photo and I don't think anyone will be able to tell when it's strung in the corset backing either.

Step seven: lace and sew up

This is simple; lace up your dress, make sure the length is correct, snip off the excess and then you can just turn the ends inward and either hand stitch or run them over with the sewing machine to close the ends.

Ta Da!

=check!